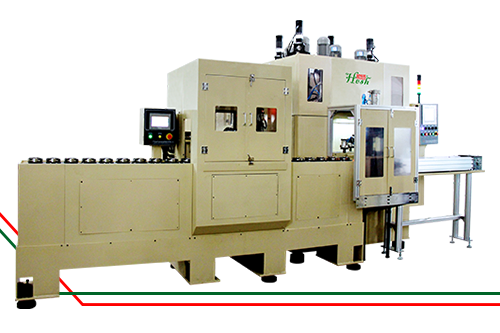

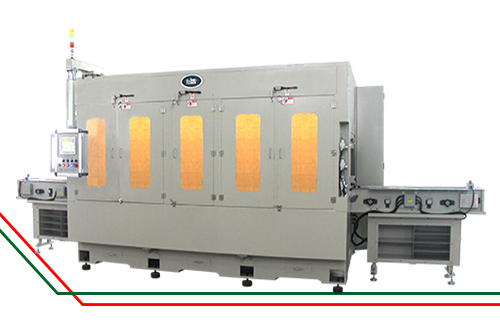

Deburring and polishing process

The truss manipulator puts the rotor on the positioning mechanism;

The transfer device automatically rotates the rotor to the deburring and polishing host;

The deburring and polishing main machine adopts a linear type, which is divided into 8 stations to automatically deburr, polish and mark the 4 parts of the rotor aluminum column top, upper aluminum table, aluminum table, and core outer circle;

1#Working station: Motor variable frequency variable speed drive milling cutter to mill the top of aluminum column;

2#Station: Motor frequency conversion variable speed drive nylon brush forward and reverse to brush the top of the aluminum column;

3#Working station: Motor frequency conversion and variable speed drive 2 nylon brushes for forward and reverse brushing on the aluminum table;

4#Working station: The turning manipulator grips the rotor and turns 180 degrees;

5#Station: Motor frequency conversion variable speed drive nylon brush forward and reverse brushing aluminum table;

6#Station: Motor frequency conversion variable speed drive nylon brush forward and reverse to brush the outer circle of the iron core;

7# station: cleaning and drying the rotor;

8# station: laser marking machine performs laser marking on the rotor;

After the rotor is processed, the loading and unloading manipulator grabs the rotor to the unloading conveyor line;

The operator removes the rotor from the aggregate conveyor line.

优势

Use dry deburring to collect impurities in a centralized manner;

Adopt the clamping method of clamping the outer circle of the rotor core;

With automatic positioning function;

With the function of counting Nissan parts;

With automatic compensation for brush wear;

It has a fault alarm reminder function to help the operator troubleshoot.

技术参数表

SPECIFICATIONS |

|

Power |

AC380V 50Hz |

Air compression |

0.4-0.6Mpa |

Pace |

≤15s |

Deburring tool |

Nylon brush, milling cutter |

Rotating speed |

0-1720rpm |

Dimension |

5557*3410*2315mm |

Weight |

6.5t |

Picture

Workpieces

- Workpieces

Contact

HESH Industry Technology Co.,Ltd.

address:No. 13 Youth Road, Hongqi Town, Jinwan District, Zhuhai City, Guangdong Province| Tel: |

(+86)756-6348028 (+86)13431909300(Mr.Zhang) (+86)13702330296(Mr.Wu) |

| Fax: | (+86)756-6324320 |

| E-Mail: | hesh@zh-heshi.com |